Welcome to our fifth and final installment of our series Understanding Glaze Components! We’ve been taking a deep dive into the primary parts that go into making successful glazes to help you increase your confidence when working with glazes. So far we’ve looked at our three foundational elements, glass-formers, fluxes, and stabilizers, as well as the all-important colorants. In today’s post we’re taking a look at opacifiers.

If you want the ability to play with the translucency or opacity of your glazes, then you’ll need to know how opacifiers work, and which ingredients to use. Let’s get started!

What Is Opacity?

Glazes can be formulated with varying degrees of clarity. In translucent glazes you can see the clay beneath the glaze. In opaque ones you cannot see the clay at all. And of course, semi-transparent or semi-opaque options are available as well. Whichever aesthetic you are aiming for, it’s important to be able to identify the ingredients in your glaze that may cause opacity, as well as the impact of firing schedules and temperatures that can have an effect as well.

How Is Opacity Achieved?

Opacity can occur from a number of factors. In some cases, microbubbles in the glaze can cause cloudiness, which can be intentional as with celedons, or as the result of improper firing.

Opacity can also be caused by an incomplete melt of certain ingredients in your glaze if it is not fired hot enough. In this instance the effect is usually undesirable, uneven, and not particularly aesthetically pleasing.

Another way in which opacity can be created is by the formation of microcrystals in the glaze. This is determined both by the ingredients used, as well as through slower firing cycles that encourage crystal growth. This crystallization creates opacity by refracting the light in many directions.

Opacity can also be produced by a mixture of glasses of differing indexes of refraction. Boron can encourage this quality in a glaze, producing a milky blue-white texture typical in rutile blue glazes.

And lastly, opacity can be achieved through the use of specific ingredients, which we’re explore in more depth. These can be broken into two basic groups: fluxes with opacifying properties under certain conditions, and opacifying oxides.

All of these opacity influencers will produce a cloudy or white effect, so other ingredients, such as those we discussed in Part 4, are needed to change the color.

Fluxes That Can Affect Opacity

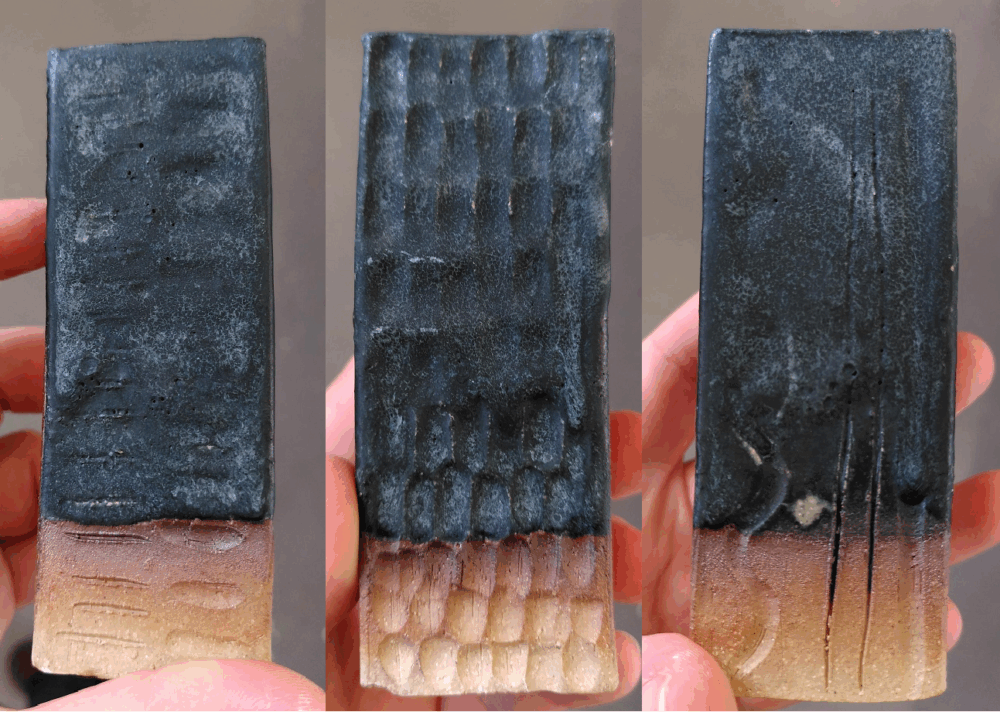

There are a number of fluxes that when used in high concentration, will produce an opacifying effect. When using these, it’s important to understand that firing temperature can affect this, and if you fire too hot, the opacity will diminish.

It’s incredibly easy to identify which fluxes will have this effect, because they all belong to the same group: the alkaline earths, which you’ll remember from Part 2 of this series. These fluxes are known for producing matt finishes, which are frequently a result of the same micro crystallization as opacity. These fluxes include calcium oxide, magnesium oxide, barium oxide, and strontium oxide. For more detail on these ingredients, be sure to read Part 2 if you missed it!

Opacifying Oxides

These oxides are ones that are included in a recipe specifically for their opacifying properties, and play a minimal role in terms of the core components of a glaze. There are a few commonly used opacifying oxides you’ll come across, so let’s take a closer look below.

Tin Oxide (SnO2)

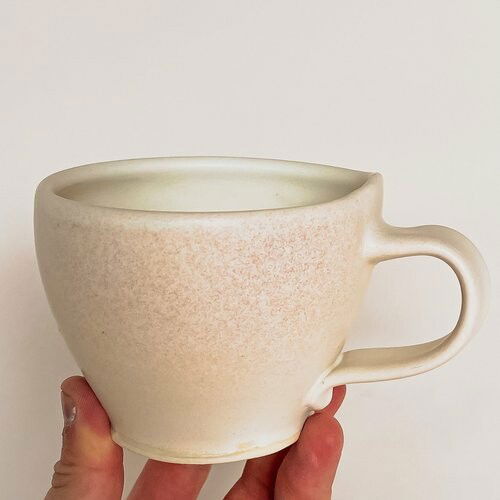

Tin oxide is a very common opacifier in oxidation firings, and is effective across a broad range of temperatures. It’s a metallic oxide probably best known as the key ingredient in the milky-white base glaze for majolica ware. It is excellent for producing smooth, glossy surfaces. 1-3% gives semi-opaque and cloudy results, with 6% – 10% giving cream – white.

In addition to its opacifying qualities, tin is commonly used in conjunction with colorants to produce unique effects and colors. When used with chrome it will produce pink, and with iron will produce a lovely warm brown. It can also create interesting variegated effects when used with rutile. Tin is a fairly expensive ingredient, so it’s sometimes substituted with cheaper options, such as:

Zirconium Dioxide (ZrO2)

Zirconium oxide is another metallic oxide, and has comparable opacifying properties to tin. In glazes it’s usually used in the form of zirconium silicate, and is sold under a variety of brand names, such as Zircopax, Superpax, and Opax. It is a less powerful opacifier than tin, so more is needed to achieve the same effect, but its lower cost makes this a fair trade off. 8% will make most glazes opaque with 12% producing white. Zirconium has the added effect of increasing the hardness of a glaze, and is more effective in reduction than tin.

Titanium Dioxide (TiO2)

Titanium oxide is our third major opacifying oxide and is well known for its promotion of crystals, which is the mechanism of its opacity. It’s not quite as effective as tin or zirconium, but is used in smaller amounts of around 6% or less. In higher amounts it can cause pinholing.

It’s a common ingredient for achieving variegated colors, as well as a key feature in many crystalline glazes. It also has the effect of softening colorants.

You may have noticed that the chemical names for these materials (SnO2, ZrO2, TiO2) are very similar. These are our RO2 oxides, where each carries two oxygen molecules. You may remember us referring to our fluxes as RO and R2O oxides. If you see an RO2 oxide in your recipe, it’s a good indicator that it’s an opacifier, with the exception of Silica, which is also an RO2 oxide but does not opacify.

As we bring our series on Understanding Glaze Components to a close, we’ve turned our attention to opacifiers, the final piece of the puzzle in creating successful glazes. Throughout our journey, we’ve explored the foundational elements of glazes, from glass-formers and fluxes, to stabilizers, and delved into the world of colorants. Each contributes to the depth and beauty of ceramic surfaces. Now, having uncovered the secrets of opacifiers, you’re equipped with the knowledge to manipulate the translucency or opacity of your glazes, opening up a broader world of creative possibilities.

Whether you’re seeking to enhance the visual impact of your glazes or explore new avenues of artistic expression, understanding the role of opacifiers is key. Armed with this newfound insight, you can embark on your glazing endeavors with confidence and creativity.

And don’t forget, glazes aren’t the only way to embellish your ceramic surfaces. Be sure to check out Diana Fayt’s workshop “Creative Stencils,” and Nikki Mizak’s “Watercolor Style Underglaze Illustrations” for plenty of tips and tricks for bringing illustration and decoration into your ceramic pots.

Responses