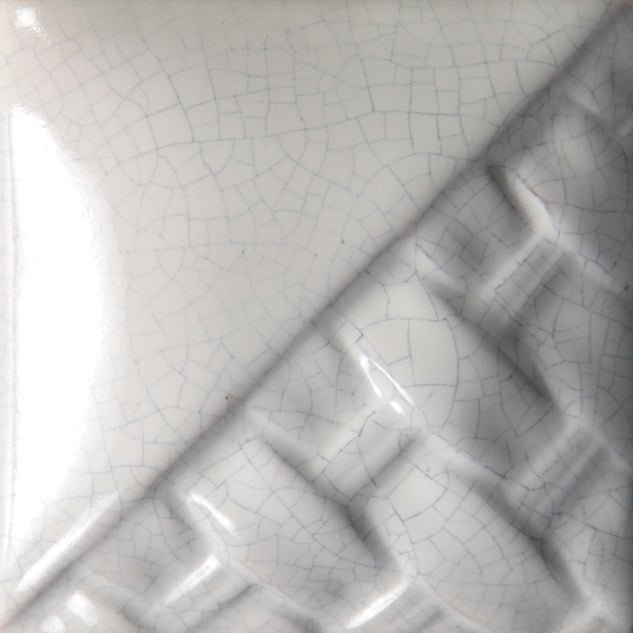

Stoneware crackle was developed for mid-range firing temperatures where a fine crackle pattern will develop with 2-3 coats. After firing, wipe an acrylic or ink over the ware and wipe off, allowing the ink to fill and highlight the cracks. The thickness of the glaze and the cooling rate will affect the crackle formation. We recommend you start with three brushed-on coats and use a medium firing program. Crackle pattern works best with a thicker application.

Chips shown are fired flat on a white clay body fired to cone 6 oxidation and cone 10 reduction. The choice of clay body, the thickness of glaze application, the firing process, and temperature will affect the fired results.

Cone 6 oxidation : Crackle White is a bright white gloss glaze that develops a fine crackle pattern. Works well on stoneware and porcelain bodies and produces crackle patterns at midrange temperatures. Use India ink to highlight or accentuate crackle patterns.

Cone 10 reduction : Turns an orange-brown and pools white in texture when thick. The glaze does not crackle.

Description:

The Ceramic School

At The Ceramic School, we are driven by a vision of a world where the transformative power of ceramics is accessible to all, inspiring creativity, celebrating diversity, and promoting sustainability, to contribute to a vibrant global community of artists and makers.

All Posts