If you’re quite new to ceramics, or you live somewhere with limited ceramic resources, chances are the bulk of your firing experiences have been with an electric kiln. And there’s a good reason for this! Electric kilns are easy to use, produce reliable and consistent results, and are affordable to fire. However, you may have noticed that there are some glaze and surface effects that are just not possible with the electric kiln. For these, a fuel-burning kiln is the answer.

Welcome to our brand new three-part series, where we’re embarking on a journey into the fundamentals of fuel-burning kilns and firing processes. In Part 1 of this series we’re taking a look at the types of effects made possible by fuel-powered kilns, followed by Part 2, where we’ll delve into the types of fuels commonly used in these kilns. And in Part 3, we’re going to cover the three main design types of fuel-burning kilns.

Join us as we discover the unique properties and possibilities of fuel-burning firings!

Electric vs Fuel-Burning: What’s the Main Difference?

While the electric kiln has become the mainstay for many studio potters and community studios, in the evolution of kilns, it’s a relative newbie on the scene. The very first ceramic kilns date back to 6000 BCE in what is now Iraq, while the electric kiln was only invented in the 20th century. Its invention was a complete game changer, allowing for the creation of smaller kilns that could be used at home or in school, as well as offering an oxidation environment throughout the firing. Oxidation firings in turn allowed for more consistent and predictable results, as well as high firing temperatures with a greater degree of control over the firing schedule.

So with such a huge technological advancement, why do so many artists prefer fuel-burning kilns like wood or gas? Well, for many ceramicists, it’s exactly the unpredictability of these firing processes that make them so appealing!

Reduction

Probably the number one reason you’ll find people moving towards fuel-powered kilns is for their reduction firing capability. We mentioned that electric kilns create an oxidation environment, which means that the kiln has consistent oxygen availability inside during the firing process. This is possible because electricity heats with current, rather than combustion. With fuel-burning kilns we’re relying on combustion to generate the heat, which put simply, is the reaction of oxygen with other substances (our fuel). As this reaction happens, the oxygen is used up. Depending on how much air we allow to enter the kiln during the firing, this effect can be increased or decreased throughout the firing. When we deprive the kiln of oxygen we create a reduction environment.

It is worth noting that reduction is technically possible in an electric kiln by adding combustible materials, but this will greatly reduce the life of your elements, and requires increased ventilation.

Reduction is desirable in firing because it causes glaze reactions that are not otherwise possible. You may remember from our Understanding Glaze Components series that the majority of our glaze ingredients are oxides. When there is insufficient oxygen in the atmosphere of the kiln, the fire will pull the oxygen out of the glaze. This effectively changes its chemical composition, and often its appearance.

Air Flow

The other big difference with fuel-burning kilns is that they have atmospheric movement. The flame moves and dances about the kiln, pulled by the suction of the flue and the chimney. This causes uneven glaze effects, particularly when other materials are added during firing. The result is pots that can never be completely replicated, with every fired load being unique. This is further enhanced by the unique design characteristics of each type of kiln (and even each individual kiln) which we’ll cover more in Part 3.

Other Reasons to Choose Fuel-Burning Kilns

Before we look at some of the specific effects and processes made possible by fuel-burning kilns, there are a few non-aesthetic reasons artists may choose this type of kiln, so let’s have a look.

A major benefit of these kilns is that you can set them up off grid. While natural gas will be reliant on a supply, oil, propane, wood, and smaller pit setups do not require any external connections. You’ll never be affected by a power outage, and you won’t need to upgrade the electrics in your home to accommodate the kiln.

Fuel-burning kilns can be custom built. You don’t need to be an electrician to build a fuel-burning kiln. With schematics and guidance from an experienced kiln builder, you can build a kiln for your fuel of choice with the size and features that best suit your practice.

Fuel-burning kilns are well-suited to the outdoors. While they do require a concrete slab base and sufficient cover from the elements, they are safe to operate outside. They can be used indoors as well, but keep in mind that they require much better ventilation than electric kilns due to the fumes created by the burning process.

Processes Made Possible with Fuel-burning Kilns

A number of unique firing processes are only possible with the atmospheric or reduction environments of fuel-burning kilns. Here are some of the most common:

Salt Firing

Salt firing is achieved by introducing salt into the kiln during the firing process. This is done by inserting the salt through special ports in the side of the kiln at around 2192F (1200C). This produces a vapor that releases chlorine gas, leaving behind the sodium of the salt to combine with the silica and iron in your pots. It creates a characteristic orange peel effect that’s instantly recognizable. The salt glaze itself is clear, but is commonly used in combination with colored slips, such as those with cobalt.

Most potters will have kilns specifically for salt firing as the salt not only glazes the pots, but everything else inside the kiln, including the bricks. With each firing this glaze will re-vaporize, affecting the current ware load, so you don’t want to put pots in a salt kiln if you aren’t after this effect. The salt is also highly corrosive, so these kilns tend to have a shorter lifespan than other kiln types. As you can imagine, this type of firing would severely damage the elements of an electric kiln.

Now you may have caught that we said a byproduct of this process is chlorine gas. This is a respiratory toxin, so great care and ventilation is required when firing so as not to expose yourself and your neighbors to any harmful effects. For those of you concerned about your environmental impact, this may not be the best choice for you, as the gas is also harmful to the environment.

Soda Firing

While not a new process, soda firing has experienced a bit of a resurgence in the last few decades as a safer and more environmentally-friendly alternative to salt firing. It’s also a vapor process that relies on the use of sodium for a glazing effect, but in this case the sodium is supplied by soda ash or sodium bicarbonate which eliminates the production of chlorine gas. And while it can produce a similar orange peel effect, it tends to have a softer aesthetic with areas of rich orange flashing. Like salt firing, soda is also commonly used in conjunction with a slip, and the material is introduced to the kiln through special ports midway through the firing.

Raku Firing

Raku firing is a bit of an outlier here in that the reduction actually happens outside of the kiln, in what we call post-fire reduction. What we commonly think of as raku today is perhaps more accurately known as North American raku, as the tradition from which it gets its name did not include post-fire reduction.

Raku kilns are typically gas fired, and the reason for this is that the kiln is opened while at around 1832F (1000C), a process that is not very good for electric kilns. While still glowing red hot, the pots are placed in beds of combustibles which immediately catch fire, and are then covered tight to create the reduction.

This process creates a signature blackened clay body, with crackle and high-metal glaze being used for unique and vibrant results.

Smoke Firing

The earliest of all firing processes, smoke firing involves firing unglazed work in combustibles, usually in a pit or a saggar (a special-built closed clay pot). The materials not only fire the pot, but add characteristic black patterns to the pots as they absorb the carbon from the smoke. Some special combustibles, such as seaweed or banana peels can give subtle orange and red patterns. While we may not think of a pit as a kiln, it still has all of the core elements needed to transition clay to ceramic. Pit firing does not fire very hot however, and will not bring stoneware clays to maturity.

Glazes that Must Be Fired in Fuel-Burning Kilns

In addition to the above processes, there are a number of glazes that can only achieve their characteristic effects when fired in reduction. You’ll likely be familiar with most of them as they are well known for their beautiful, and sometimes elusive, colors and surfaces. Many of them also have long histories surrounded with story and legend, and for this reason are often favored by potters with a love of history (and perhaps a bit of a romantic leaning).

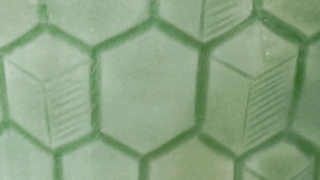

Celadon

An iconic glaze that comes to us from ancient China, Celadons are easily recognized by their characteristic blue-green color. Celadon is a high-fired reduction glaze used on stoneware and porcelain, and can feature either a smooth, glossy surface or an opaque and waxy one (with the latter being more traditional). Its signature color is achieved through the use of iron oxide, and it also tends to have high sodium/potassium and high silica levels.

Cooper Reds/Oxbloods

One of the most romanticized of the reduction glazes, copper red produces an unparalleled red that is challenging to achieve. It was first used in China roughly 1000 years ago, and is often referred to as Oxblood, due to the blood-like color that it can produce. This glaze requires a very controlled reduction, though surprisingly low amounts of copper.

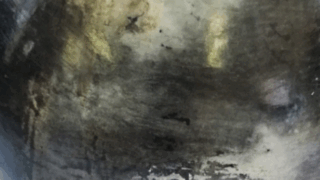

Tenmoku

These are high-iron and very fluid glazes that create a unique dark/near-black surface that breaks orange/brown over edges and surface textures where it becomes thinner. With about 10% iron oxide, some crystallization can occur, which contributes a unique stardust-like effect that characterizes the glaze.

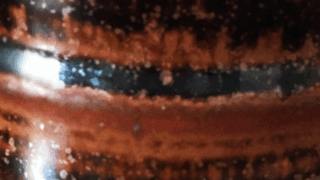

Shino

Shinos are beautiful glazes originating from Japan, and are known for a number of unique characteristics. They tend to have a color range from deep orange to white, being paler when applied thicker. They are also prone to what would normally be considered glaze faults, but here are desirable aesthetic effects: crawling, pinholing, and crazing. They can develop an almost metallic sheen in areas, and are often used for their ability to produce carbon-trapping. The latter occurs in very high-reduction atmospheres, when black carbon particles create pleasing spots and blotches in the glaze.

Shinos are in essence composed of two primary ingredients: High alumina and high sodium feldspars, and clay.

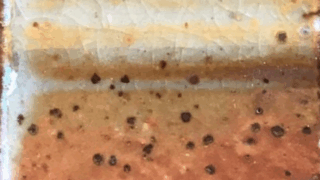

Ash Glaze

Now, this one is a bit of an outlier, in that ash glazes can indeed be fired in electric kilns, and you can mimic the characteristic drips and movements of those created in a fuel-burning kiln. However, it is hard to get the truly uncontrolled and surprising effects of ash that are created in wood kilns.

Ash glaze can be mixed and applied to the pot using the ash of organic materials along with other glaze ingredients, but it is also a natural glazing effect that occurs in a wood fired kiln as the burning wood distributes ash throughout the firing chamber and onto the pots. This burning ash acts as a natural flux, turning matt glazes glossy, and creating a glaze on previously unglazed surfaces. It’s typically near-clear and ranges from pale yellow to green, but will also react with ingredients on already glazed pots.

As we wrap up our introduction to this exciting three-part series, we’re reminded of the pivotal role that fuel-burning kilns play in expanding the horizons of ceramic creativity. While electric kilns are often favored for their convenience and reliability, the limitations they impose on certain glaze effects can compel us to explore alternative firing methods. In the forthcoming installments, we’ll continue our comprehensive exploration, looking at the impacts of fuel selection and the nuances of different kiln types. Together, let’s unlock the full spectrum of creative possibilities that fuel-burning kilns offer!

If you’d like to learn more about fuel-based firing processes, be sure to check out the replays for our Clay Camp Glazing and Firing event – where we go through a whole bunch of features of each of these processes in an easy-to-follow manner, while adding in some great throwing tips for good measure!

Responses