What is an Electric Kiln?

For modern potters and ceramicists, it is impossible to finish your work without a kiln of some kind. In this age of modern technologies, many potters will choose to go with an electric kiln rather than using a gas kiln. Electric pottery kilns can come in an assortment of sizes, features, capacities, firing temperatures, and prices. This allows everyone to pick an electric kiln that is just right for the type of work that they are creating: from the novice to the semi-serious hobbyist, teachers, or professional ceramicists who need to mass produce their work.

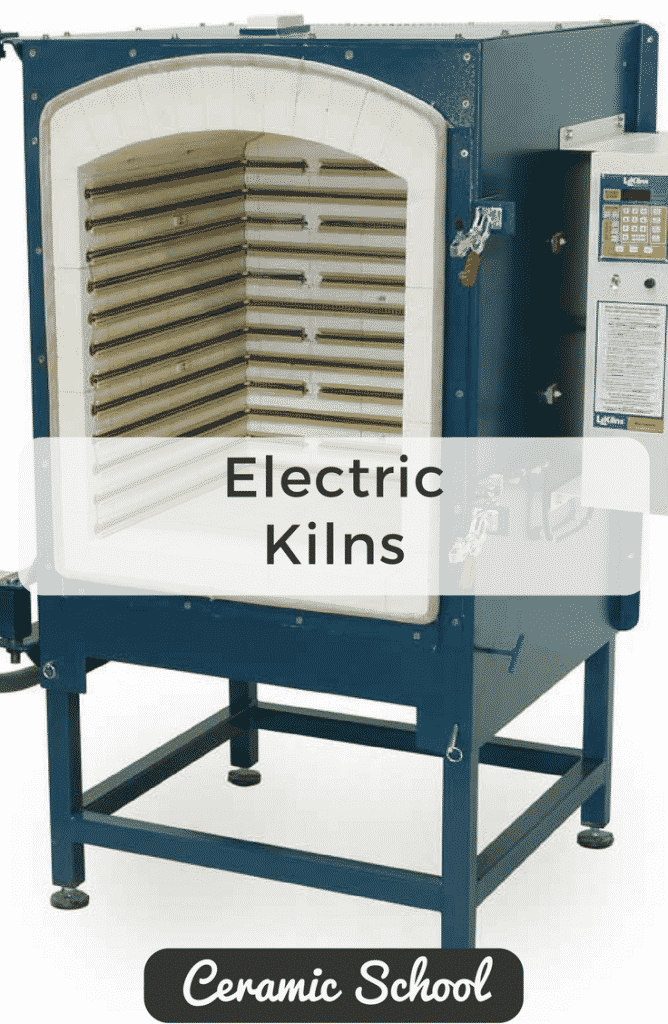

When you compare electric kilns to the alternatives of wood and gas-powered kilns, they are far less complicated and easier to operate effectively. You may be wondering – what exactly is an electric kiln? A simple explanation of an electric kiln can be divided into the following elements: an enclosed metal box that is lined with an insulating material, and grooves that are lined with special coils made of metal alloy that run along the entirety of the inside of the kiln. These coils heat up and the insulated bricks keep the heat inside more regulated and hold the temperature for longer.

Additionally, there are two options for how you can control your kiln. This is either an automatic electric controller or a manual controller that you are responsible for turning up yourself.

Manual Electric Kiln Sitters

The manual controller requires a kiln sitter and pyrometric cones. This means you have to turn the switches up yourself and use the kiln sitter to monitor the temperature inside of the kiln. This is a less preferred option for those who do not want to have to regulate every temperature raise in the kiln.

Automatic Electric Kiln Controllers

Electronic controllers are relatively easy to program and usually include pre-made profiles from the manufacturer. This is a convenient and streamlined method for running a kiln which is typically the most preferred option for those who are used to other modern, streamlined conveniences.

5 reasons why you should choose an electric kiln.

Electric Kilns are Affordable

Electric kilns are far more affordable compared to their gas and wood-fired alternatives. This makes it easier for potters and ceramicists with a lower income to save up and buy the most critical tool that they need to complete their work. The reason why electric pottery kilns are inexpensive is because the manufactures produce enough kilns that they can negotiate the cost of raw materials, parts, and the production process itself to make sure the cost of producing a single kiln is as low as possible for them. Another cost saving advantage is that electric kilns are faster and less costly to operate compared to alternative kilns of the same size.

Electric Kilns are Convenient

Electric kilns require significantly less work when it comes to firing compared to a gas or wood-fired kiln. Depending on the controller that you’re interested in getting for the kiln, you can place your work inside the firing chamber, turn on the kiln, and walk away – all without having to babysit the kiln while it fires. The kiln will fire for the specific time that you programmed and turn itself off after it completes its cycle. There are even small to medium kilns that can plug into conventional domestic electric outlets. This means that you do not need an electrician to configure your outlet for higher voltage currents. This convenience even allows you to take your kiln with you to other locations if you travel for work.

Electric Kilns are Reliable

Electric kilns are very reliable and predictable, primarily because you program the firing schedule yourself using a controller. This allows you to decide how you want your work to be fired, and allows you to change the conditions quite easily with either the press of a few buttons or the turn of a few dials. Electric kilns are very accurate and if you don’t like your firing schedule you can easily adjust it on the fly as needed. This is significantly easier and considerably less work for the user compared to using wood or gas-fired kilns, where they must be constantly monitored and cannot be easily adjusted during a firing. Without constant attention, the results of these kilns can be affected negatively by factors beyond the control of the user.

Electric Kilns are Flexible

Depending on the size of the kiln you purchase, you can run smaller kiln loads in small to medium sized electric kilns. This allows you to produce more small batches of work and is convenient for testing glazes, clays, decals, lusters, and other firing processes. If you were to do the same in a wood or gas kiln it would not be economical or even feasible as they tend to be larger and require the kiln to be fully loaded to get the proper results.

Electric Kilns are Quick

One of the biggest advantages of using an electric kiln is that it is much faster to heat up and cool down. Depending on the firing schedule you choose it is possible to run and empty a kiln within 24 hours. This is very convenient for both production and hobbyist potters who don’t want to wait two full days or more as is common with atmospheric kilns.

Different Types of Electric Kilns

One of the main options you will have to choose from when it comes to an electric kiln is whether you want a front loading electric kiln, or a top loading electric kiln.

Front-Loading Electric Kilns

A front-loading kiln has a hinged door located on the front facing side of the kiln. To explain in a simpler manner, a front-loaded kiln consists of a metal box with a door on the front of it, which you can open and then load your work in on the shelving as if you were loading a pantry. This front-loading design is popular in larger kilns that are both more complicated and expensive. The most common design seen with front-loading kilns is to use a heavy steel frame so that it can support the bulky bricks that line the interior of the kiln.

Top Loading Electric Kilns

A top-loading kiln is mainly used in small to medium electric kilns. When you are shopping on a budget this is the design you should go with because they are associated with less expensive kilns. These small to medium kilns are usually shipped as an assembled unit, but can be disassembled into segments to allow easier transportation. These kilns can be either sold with a manual or electric controller depending on the kiln you choose.

Top-Loading Electric Kilns Vs. Front-Loading Electric Kilns

When you are looking to purchase either of these types of kilns you must be considerate of your needs and think about the components of the kiln so that you can prolong the life of your kiln and get the best return on your investment.

When it considering purchasing a front-loading kiln you will need to examine the door, hinges, and roof. Check the quality of the metal bracing, especially around the door area where the most abuse will occur over time. The door should be robustly made and the handles should be well insulated. The best hinges are adjustable because they allow you to adjust the fit of the kiln as needed and the hinges should be out of the heat path and not friction prone. The roof should be examined to ensure that it is structurally sound, but not unwieldy or too heavy. The best type of roof is a sprung arch roof since it is both long-lasting and strong.

Top-loading kilns do not require as much of a critical examination; but you should consider the depth of the kiln, hinges, and floor-mounted heating elements when shopping for a kiln. Older kilns tend to be taller and more compact, while modern kilns are typically wider than they are taller. This means that it is easier to load the kiln if it is wider and shorter compared to taller, because you don’t have to bend over as much. Hinges for top-loading kilns must sustain even bigger loads and abuse than a front-loading kiln, so it is best to check the strength of the hinges to ensure they turn freely when the lid is opened or closed. The best feature of a top loading kiln is the heating elements at the bottom of the kiln. This ensures that the bottom of the kiln is just as hot as the top and sides of the kiln and allows a more even temperature throughout the kiln. Not all top loading kilns will have this, but it is a good feature to have in your kiln and allows for more versatility with your firing schedules.

Size Options for Electric Kilns

There are many different sizes and shapes that electric kilns can come in and this gives a lot of options for different people in the clay world. Some of the most standard sizes are listed below:

- Up to 9″x11″

- 18″x18″

- 23″x27″

- 29″x27″

When looking at the list above think about what ware you produce the most. Functional work? Sculptural work? It is best to fill the kiln completely to maximize efficiency and to keep the costs of firing your kiln down as low as possible. Remember to consider how long it will take you to fill your kiln up to the top. Smaller kilns are best for those who do not produce a large amount of work in a short period of time, while larger kilns are best for those who are mass producing their work in a short span of time. The 9″x11″ are best for small items and test kilns, the 18″x18″ are good for small pieces and hobbyists that don’t produce a lot of work, the 23″x27″ is the most common size for the average potter and the 29″x27″ is the best for mass production work.

Electricity Requirements for Electric Kilns

There are many other aspects that can be discussed when it comes to electric kilns such as venting, brand options, kiln furniture, and others. However, one aspect that is extremely important to consider is the electricity requirements of your electric kiln. Most homes have either 120-volt or 240-volt single phase outlets available. If you are in an industrial or school area, you may have 208-volt or even 480-volt outlets. You don’t choose your voltage as much as it is decided by the power you have available to you. If you are wanting a 240-volt single phase, be sure to check the voltages in your location to be sure that is what is available to you. It is always a good idea to call in an electrician who can provide an estimate and can install a breaker that meets the proper amperage requirements for the electric kiln that you have. The price for an appropriate breaker can be around $200-$300, but if you need to bring more power into the house in order to run your kiln it can cost you thousands of dollars. This is why you should always check your electricity requirements before purchasing an electric kiln, so you don’t end up choosing the wrong type of electric kiln.

Conclusion

When it comes to choosing your electric kiln, it can be very overwhelming, but once everything is picked out and the electric kiln arrives the excitement can drown out the previous feelings. There is no other feeling in the world that can compare to the first successful firing in your brand-new electric kiln and the continued success of firings after that. Using this overview and the advice within will help you with deciding what kiln you should get and makes the whole process a little bit smoother.

Responses